Fa'idodi Da Iyakance Na Gyaran Allura

An yi muhawara game da fa'idar yin gyare-gyaren allura fiye da gyare-gyaren simintin gyare-gyaren mutun tun lokacin da aka fara gabatar da tsohon tsari a cikin 1930s. Akwai fa'idodi, amma kuma iyakance ga hanyar, kuma, da farko, tushen buƙatu ne. Masana'antun kayan aiki na asali (OEM) da sauran masu amfani waɗanda suka dogara da sassa masu gyare-gyare don samar da kayansu, suna neman irin waɗannan abubuwa kamar inganci, karɓuwa da araha wajen yanke shawarar waɗanne sassa gyare-gyaren da suka dace da bukatunsu.

MENENE CUTAR ALLURAR?

Yin gyare-gyaren allura hanya ce ta ƙirƙirar ƙayyadaddun sassa ko samfura ta hanyar tilasta narkakkar robobi a cikin gyaggyarawa da barin ta taurare. Amfani da waɗannan sassa ya bambanta sosai kamar nau'in samfuran da aka yi daga tsarin. Dangane da amfani da shi, sassan alluran da aka ƙera na iya yin awo daga ƴan oza har zuwa ɗaruruwa ko dubban fam. Wato, daga sassan kwamfuta, kwalabe na soda da kayan wasan yara, zuwa manyan motoci, tarakta da sassan mota.

MENENE MUTUWA YIN JAM'I

Die simintin gyare-gyare tsari ne na masana'antu don samar da daidaitattun ƙira, ƙayyadaddun ƙayyadaddun ƙayyadaddun, santsi ko sassa na ƙarfe mai laushi. Ana cim ma ta ta hanyar tilasta narkakkar karfe a ƙarƙashin babban matsi cikin mutuwar ƙarfe mai sake amfani da shi. Yawancin lokaci ana kwatanta tsarin azaman mafi ƙarancin tazara tsakanin albarkatun ƙasa da ƙãre samfurin. Hakanan ana amfani da kalmar "dige simintin gyare-gyare" don kwatanta ɓangaren da ya ƙare.

FALASTIC INJECTION MOLDING VS. MUTU KASANCEWA

Hanyar yin gyare-gyaren allura ta asali an yi ta ne akan simintin gyare-gyaren mutu, irin wannan hanya wadda ake tilastawa narkakkar ƙarfe a cikin wani nau'i don samar da sassa na samfuran da aka ƙera. Koyaya, maimakon yin amfani da resin robobi don samar da sassa, simintin mutuwa yana amfani da galibin ƙarfe marasa ƙarfe kamar zinc, aluminum, magnesium, da tagulla. Ko da yake kusan kowane bangare za a iya jefa shi daga kusan kowane ƙarfe, aluminum ya samo asali a matsayin ɗayan shahararrun. Yana da ƙarancin narkewa, wanda ya sa ya zama mai sauƙi don sassaƙa sassa. Mutuwar ta fi ƙarfi fiye da ƙirar da aka yi amfani da su a cikin tsarin mutuwa na dindindin don jure allurar matsa lamba, wanda zai iya zama psi 30,000 ko fiye. Tsarin babban matsin lamba yana haifar da dorewa, tsari mai kyau tare da ƙarfin gajiya. Saboda haka, yin amfani da simintin gyare-gyare na mutuwa ya bambanta daga injuna da sassan injin zuwa tukwane da kwanoni.

Mutuwar Fa'idodin Yin Casting

Mutuwar simintin gyare-gyare yana da kyau idan bukatun kamfanin ku na da ƙarfi, ɗorewa, sassa na ƙarfe da aka samar da yawa kamar akwatunan mahaɗa, pistons, kawunan silinda, da tubalan injin, ko masu tallatawa, gears, bushings, famfo, da bawuloli.

Mai ƙarfi

Mai ɗorewa

Sauƙi don samar da taro

Ƙayyadaddun Ƙirar Casting

Amma duk da haka, za a iya cewa, ko da yake jefar da mutuwa yana da fa'idojinsa, akwai iyakoki da dama a cikin hanyar da za a yi la'akari da su.

Iyakantattun masu girma dabam (mafi girman kusan inci 24 da 75 lbs.)

Babban farashin kayan aiki na farko

Farashin karfe na iya canzawa sosai

Kayan tarkace yana ƙara farashin samarwa

Amfanin Gyaran allura

Amfanin gyare-gyaren allura ya sami karbuwa a cikin shekaru da yawa saboda fa'idodin da yake bayarwa akan hanyoyin masana'antar simintin mutuwa na gargajiya. Wato, babban adadi da iri-iri na ƙananan farashi, kayayyaki masu araha waɗanda aka yi daga robobi a yau ba su da iyaka. Hakanan akwai ƙarancin buƙatun kammalawa.

Haske-nauyi

Mai jurewa tasiri

Mai jure lalata

Mai jure zafi

Maras tsada

Ƙananan buƙatun kammalawa

Ya isa a faɗi, zaɓin wace hanyar yin gyare-gyaren da za a yi amfani da ita za a ƙaddara ta ƙarshe ta hanyar haɗin kai na inganci, larura, da riba. Akwai fa'idodi da iyakancewa a kowace hanya. Wace hanyar da za a yi amfani da ita — gyare-gyaren RIM, gyare-gyaren allura na gargajiya ko yin simintin gyare-gyare don samar da sashi — za a ƙayyade ta buƙatun OEM na ku.

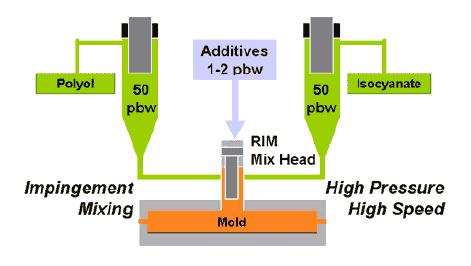

Osborne Industries, Inc., yana amfani da tsarin gyare-gyaren amsawa (RIM) akan ayyukan gyare-gyaren allura na gargajiya saboda har ma da ƙananan farashi, dorewa, da sassaucin samarwa da hanyar ke bayarwa ga OEMs. Yin gyare-gyaren RIM ya dace da amfani da robobin thermoset sabanin thermoplastics da ake amfani da su wajen gyaran allura na gargajiya. Plastics na thermoset suna da nauyi, musamman ƙarfi da juriya na lalata, kuma musamman manufa don sassan da ake amfani da su a cikin matsanancin zafi, zafi mai zafi, ko aikace-aikace masu lalata sosai. Kudaden samar da sashin RIM yana da ƙasa, kuma, har ma tare da matsakaici da ƙananan ƙarar gudu. Daya daga cikin manyan abũbuwan amfãni ga dauki allura gyare-gyare shi ne cewa yana ba da damar samar da manyan sassa, kamar abin hawa kayan aikin panels, chlorine cell hasumiya, ko truck da trailer fenders.

Lokacin aikawa: Juni-05-2020